Offhore/Subsea

Astrup AS supplies materials for Offshore and Subsea through one of our largest customer segments – the machining sector. With the focus on documentation, traceability and delivery precision, Astrup aims to be a preferred supplier to the Offshore/Subsea industry. Our materials are of a high quality, satisfying requirements and specs such as NORSOK, ASTM standards, etc. Our business partners are world-class and very familiar with supplying to Offshore/Subsea. Astrup AS is a pre-qualified supplier in Achilles JQS and also certified by the ISO 9001:2008 standard.

Reliable and durable

Oil and gas exploration occurs in some of the most demanding environments on the planet, with demands on materials including:

- Corrosive seawater

- Abrasive (sand/rock) conditions

- Exposure to sour gas and completion fluids

- Fluctuating weather conditions including, high (desert) and low (artic) temperature environments

Our materials offer the highest levels of quality and we can supply supporting documentation according to EN 10204. With 2.2 certificates with traceability on all our Technical plastic materials from stock, and 3.1 certificates on demand for projects.

Our thermoplastic materials

- Are naturally corrosion resistant

- Offer Extreme wear resistance

- Have Excellent chemical resistance

- Are weather resistant ( UV) Exhibit thermal stability in low and high temperature environments.

Astrup offer a wide range of materials and composite materials.

Proven materials for Topside applications

- Catwalk shuttle components

- Cable clamps

- Structural support

- Gratings

- Launch and recover system (LARS) components

- Cable lay equipment (sheave/sheave segments)

- Diablo rollers

- Tank support

Typical thermoplastic material

- PA6 G

- PA6 G MO

- PA6 G ESD

- POM C

- PET

- PPS

- PEEK

- PEEK CF30

Your advantages

- Naturally corrosion resistant materials

- UV and weather resistant

- Long lasting and low maintenance: Resistant to corrosive salt water and hydrocarbons

- Weight reduction ( easier install / usage)

- Noise reduction during operation

For more information (Mail)

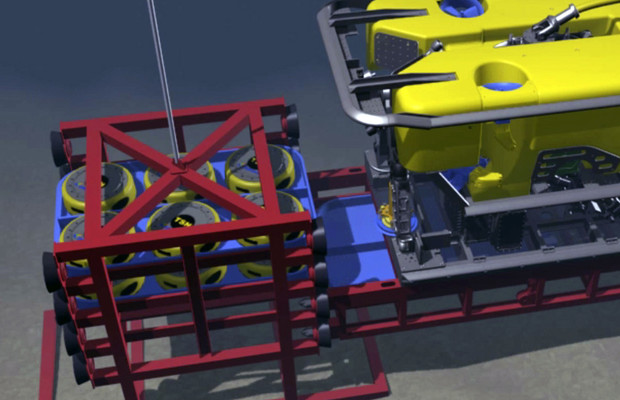

Proven materials for Subsea applications

- Pipeline systems

- ROV components

- Subsea connectors

- Support structures

- Signage

- Tree and wellhead Equipment

Typical thermoplastic material

- PEEK

- PVDF

- PEHD500

- POM

- PPSU, PES, PSU

- PA6G

- Glasfibre composite fasteners

Your advantages

- Naturally corrosion resistant materials

- Weight reduction (reduce need for costly buoyancy)

- Long, lasting and low maintenance resistant to corrosive salt water and hydrocarbons

- Economic advantages: possibility for cathodic protection free equipment

For more information (Mail)

Sales Office Oslo

Astrup AS, Oslo

Haavard Martinsens vei 34, N-0978 Oslo

Postbox 8 Haugenstua, N-0915 Oslo

Contact persons

Sales Office Skien

Astrup AS, Skien

Rødmyrlia 20A, N-3740 Skien

Contact persons

Sales Office Stavanger

Astrup AS, Stavanger

Luramyrveien 40, N-4313 Sandnes

Sales Office Bergen

Astrup AS, Bergen

Leirvikflaten 3, N-5179 Godvik

Postbox 2434 Drotningsvik, N-5834 Bergen

Sales Office Ålesund

Astrup AS, Ålesund

Lerstadveien 545

6018 Ålesund

Contact persons

Sales OfficeTrondheim

Astrup AS, Trondheim

Ingvald Ystgaardsveg 15, N-7047 Trondheim

Contact persons

Product Department Stainless & Special Steel

Haavard Martinsens vei 34, N-0978 Oslo

P.O. Box 8 Haugenstua, N-0915 Oslo

Contact persons

Product Department Plastic

Haavard Martinsens vei 34, N-0978 Oslo

P.O. Box 8 Haugenstua, N-0915 Oslo

Contact persons

Product Department Aluminum

Haavard Martinsens vei 34, N-0978 Oslo

P.O. Box 8 Haugenstua, N-0915 Oslo

Contact persons